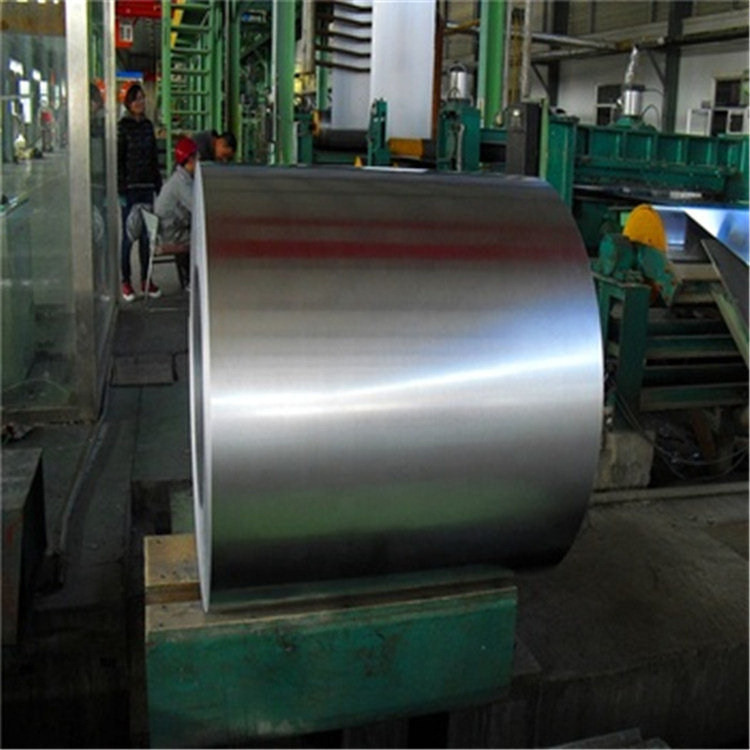

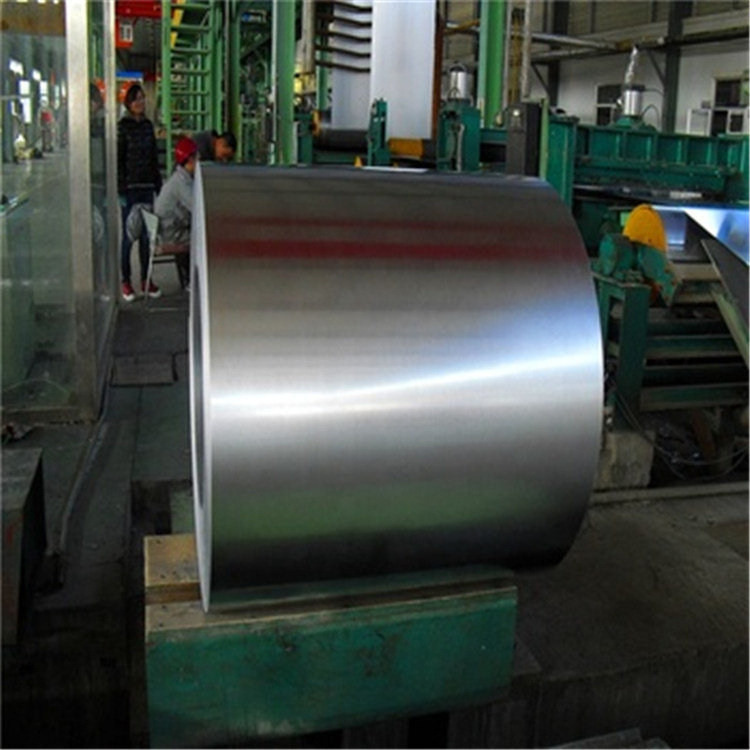

What is galvanized roll

Galvanized coil, dipping a sheet of steel into a molten zinc bath so that it adheres to a sheet of zinc on its surface. The main use of continuous galvanizing process production, that is, into a roll of steel plate continuous immersion in the melting of zinc plating tank made of galvanized steel plate, this galvanized coil has good coating tightness and weldability.

Widely used, Construction (outdoor) workshop, agricultural warehouse, residential prefabricated components, corrugated roof, wall, rainwater pipe, balcony railings, newspaper kiosk, cold storage, goods kiosk, rolling shutter door construction (indoor) door, door frame, housing light steel structure, screen, ceiling, elevator, staircase, ventilation duct electrical appliances Refrigerators, washing machines, instrument cabinets, switch cabinets, air conditioning, microwave oven, toaster furniture radiator, chimney, wardrobe, table, bed, locker, bookshelf transport cars and trains in adornment, baffle plate, container plate, police, ships across the storehouse Other to write on the whiteboard, dustbin, billboards, clocks, typewriter, dashboard, body weight, photographic equipment

galvanized coil use

Coated steel plate has light weight, beautiful appearance, can be directly processed and good corrosion resistance, it provides a new raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, electrical industry and so on, to replace wood with steel, efficient construction, energy saving, prevent pollution and other good effects.

Use galvanized steel plate for the color coating steel plate base plate, in addition to zinc protection, the organic coating on the zinc layer has the effect of covering isolation, can prevent steel plate rust, service life is longer than galvanized steel plate, according to the service life of coating steel plate is 50% longer than galvanized steel plate.

In different area and different use place, use the chromatic coating board of thickness of same galvanized quantity, same coating, same coating, its service life can have very big difference. For example, in industrial areas or coastal areas, due to the action of sulfur dioxide gas in the air or salt, the corrosion rate is accelerated and the service life is affected. In the rainy season, the coating is soaked by rain for a long time, or in the part of the day and night temperature difference is too large easy to dew, will be quickly corroded, the service life will be reduced. Buildings or factories made of colored coated steel plates often have a long service life when they are washed by rain, otherwise they will be affected by sulfur dioxide gas, salt and dust. Therefore, in the design, if the greater the tilt of the roof, it is not easy to accumulate dust and other dirt, the longer the service life; For those areas or parts that are not frequently washed by rain, water should be washed regularly.

galvanized coil coating definition

normal zinc flower coating. Zinc layer in the normal solidification process, zinc grains grow freely formed with obvious zinc flower morphology of the coating.

small zinc flower coating. During the solidification process of zinc layer, zinc grains are artificially restricted to form as fine zinc flower coating as possible.

Zinc free flower coating. By adjusting the chemical composition of the bath, the coating has no visible zinc flower morphology and uniform surface.

Zinc iron alloy coating. Heat treatment of the steel strip through the zinc bath, so that the whole coating zinc and iron alloy layer, the appearance of the coating is dark gray, no metallic luster, in the process of violent molding is easy to powder, suitable for in addition to general cleaning, without further treatment can be directly painted coating.

difference thickness coating. For both sides of galvanized steel sheet, different zinc layer weight coating is required.

finishing is a small deformation of galvanized steel for one or more of the following purposes, cold rolling.

Improve the surface appearance of galvanized steel plate or suitable for decorative coating; So that the finished products do not see the processing of slip line (Luders line) or folding phenomenon temporarily reduced to the minimum.

galvanized coil defects

The main products are: fall off, scratch, passivation spot, zinc grain, thick edge, air knife striation, air knife scratch, exposed steel, inclusion, mechanical damage, poor performance of steel base, wave edge, ladle curvature, size, imprint, zinc layer thickness, roll printing, etc.

The main reasons for zinc layer shedding are as follows: Surface oxidation, silicon compounds, cold binding emulsion is too dirty, NOF oxidation atmosphere and protective gas dew point is too high, air fuel ratio is unreasonable, hydrogen flow is low, the furnace oxygen infiltration, the temperature of the strip into the pot is low, RWP section furnace pressure is low and the door air absorption, NOF section furnace temperature is low, Oil evaporation is not enough, zinc pot aluminum content is low, the unit speed is too fast, insufficient reduction, zinc liquid residence time is too short, thick coating.

The black spots are formed by the further oxidation of white rust. The main reasons for the black spots are as follows:

Poor passivation, passivation film thickness is not enough or uneven. Unoiled surface or residual moisture on strip surface. The strip surface contains moisture during coiling. Passivation is not fully dried. Damp or rain during transportation or storage. Product storage time is too long. Galvanized sheet and other acid and alkali and other corrosive medium contact or stored together. Finished products are allowed to be stored in the warehouse for a maximum of three months to avoid oxidation.