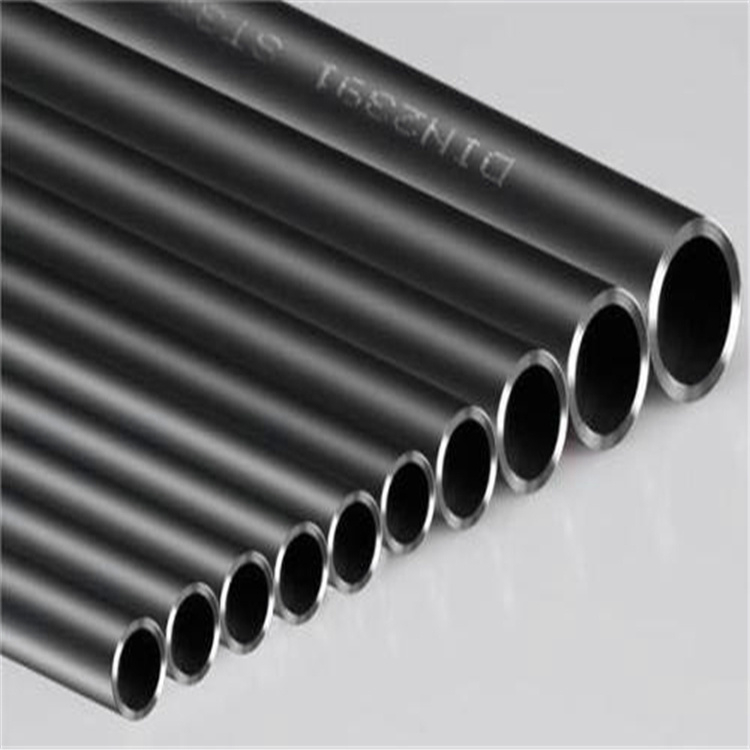

ASTM seamless black steel pipe USA is made of round steel pipe not coated with zinc or paint base material after surface sandblasting to remove the surface of the oxide, floating rust and later spraying. Seamless black steel pipe Spec 40 is a very popular type of steel pipe, especially in the USA is very widely used for transporting natural gas and water to rural and urban areas, or for protecting power lines and carrying high pressure steam and air pipes. Generally used for gas distribution inside and outside the home, Wells and sewage systems, black steel pipes are also used in the oil and petroleum industry to transport large amounts of oil through remote areas.

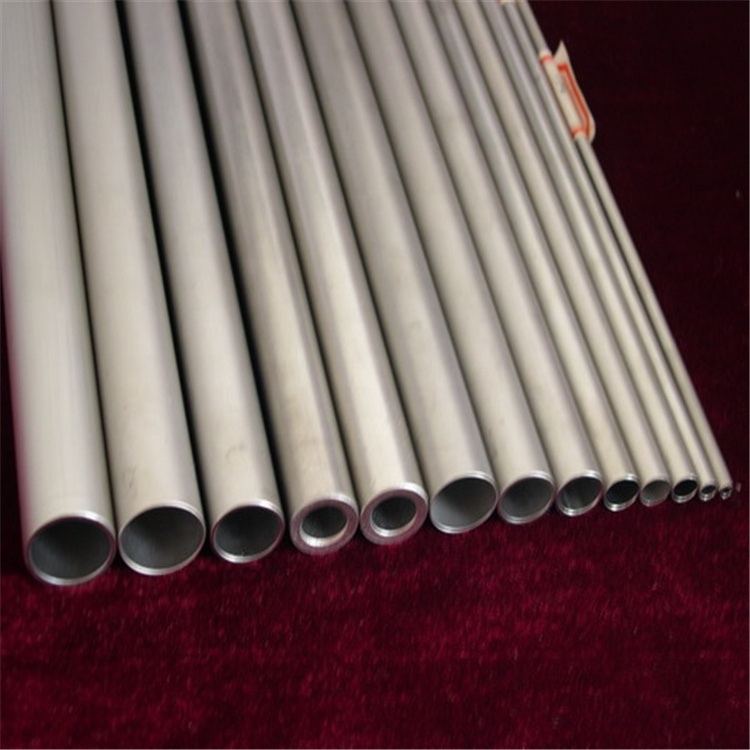

This is our seamless black steel pipe customized for customers USA. We took photos before leaving the factory. ASTM Seamless black steel pipes have been specially treated for rust prevention. Our high-quality ASTM Seamless black steel pipe has received high praise from customers.

ASTM Seamless black steel pipe Specification USA

The specification of Seamless black steel pipe is expressed in mm of outer diameter * wall thickness. Seamless steel pipe is made of high-quality carbon steel such as 10, 20, 30, 35 and 45, low-alloy structural steel such as 16Mn and 5mnv, or alloy steel such as 40Cr, 30CrMnSi, 45Mn2 and 40MnB. 10. Seamless black pipes made of low carbon steel such as 20 are mainly used for fluid transmission pipelines. Seamless black tubes made of medium carbon steel such as 45 and 40Cr are used to manufacture mechanical parts.

ASTM Seamless black steel pipe Application USA

ASTM Seamless black steel pipes are widely used, including structure, fluid transportation, low and medium pressure boilers, high-pressure boilers, chemical fertilizer equipment, oil cracking, geological drilling, diamond core drilling, oil drilling, ships, automobile half shaft casings, diesel engines, etc. Seamless black steel pipes are used. The use of Seamless black steel pipes can avoid leakage and other problems, ensure the use effect and improve the utilization rate of materials.

These seamless steel pipes may be more widely used in the USA. When purchasing these Seamless black steel pipes, you must clearly state the specific specifications of the black steel pipes.

What is difference between ERW steel pipe and seamless black steel pipe?

performance | ERW welded steel pipe | Seamless black steel pipe |

processing technic | the steel plate or strip is made by cutting, bending,welding and other processing processes | the tube blank is directly perforated and rolled |

application | transport of fuel, gas and other liquids | conveying liquids and manufacturing structural and mechanical parts |

appearance | there's a welding line | no welding wire |

suffer from stress | weaker | stronger |

costing | lower | higher |

ERW steel tubes differ from seamless steel tubes in several ways ERW tubes are used to transport liquids such as fuel gases regardless of pressure, making it one of the most typical delivery tubes in the world Seamless tubing, on the other hand, is a square or rectangular shaped steel tube with no joints around it and a hollow cross section used for transporting liquids as well as fabricating structural and mechanical parts. ERW and seamless steel tubes in general are quite different in use due to their high bending and torque strength and incredible lightness The biggest difference between ERW pipe and seamless steel pipe is that THE ERW pipe has a weld, the same as the welded steel pipe, but the black seamless steel pipe does not have, and the welded steel pipe does not have in addition, the welding line of THE ERW pipe is the key to the quality of the ERW steel pipe. The more difficult the welding line of the ERW pipe is to identify, the higher the quality of the ERW pipe.

How to identify the pipeline is ERW or seamless pipe? To identify whether a pipe is ERW or seamless, simply read the template on the side of the pipe if IT is ASTM A53,Type S means seamless; F type is furnace type but welded; Type E is resistance welding this is the easiest way to tell if a pipe is ERW or seamless.

ERW steel pipe and seamless black steel pipe for USA

There are too many differences between ERW steel pipe and Seamless black steel pipe. In the USA market, appropriate products are selected for different application scenarios. Our custom-made ASTM ERW steel pipe and Seamless black steel pipe meet USA standards.

What are the materials of seamless steel pipes?

In general, the material of seamless pipe is mainly steel. According to different production methods, it can be divided into several different types, pihot rolled pipe, cold rolled pipe, extruded pipe and cold drawn pipe. Hot rolled seamless pipe is the most common seamless pipe. Its manufacturing process is as follows: firstly, it is produced on the automatic pipe rolling mill. If the solid pipe blank is cut into the required length as required after checking and removing the surface defects, then it is centered on the end face of the perforated end of the pipe blank, and finally perforated on the piercer. It should be noted that while piercing, the steel pipe should be rotated and advanced continuously. Under the joint action of several plugs, the interior of the pipe blank will gradually form a cavity under such action. Then, after further processing, the processing of seamless steel pipe is completed.

If you want to get seamless pipes with better quality and quality, you can't use the method of separate hot rolling, but the combination of cold rolling and cold drawing. In general, cold rolling is usually made on a two high mill, while cold drawing is carried out on a cold drawing machine.

The so-called extrusion method refers to taking out those pipe blanks that are about to be heated, and then putting them into a completely closed extrusion cylinder. Through the joint movement of the extrusion rod and the perforation rod, the extrusion parts are extruded from the smaller die holes. Using this method, steel pipes with smaller diameter and higher quality can be produced.

Seamless pipe is widely used mainly because it has the following characteristics: (what are the characteristics of seamless steel pipe? I have to look through the information to tell you that Austria is like this.)

Because the manufacturing process of seamless steel pipe is relatively simple, its use also has certain limitations. Generally, the accuracy of seamless pipe is not high, the surface of pipe wall is not very uniform, the surface gloss is not very high, and there are some obvious pits.

The delivery inspection of seamless pipe must go through precise treatment. Therefore, seamless pipe has excellent performance in terms of high strength and high pressure.