Surface description and coloring of stainless steel coils

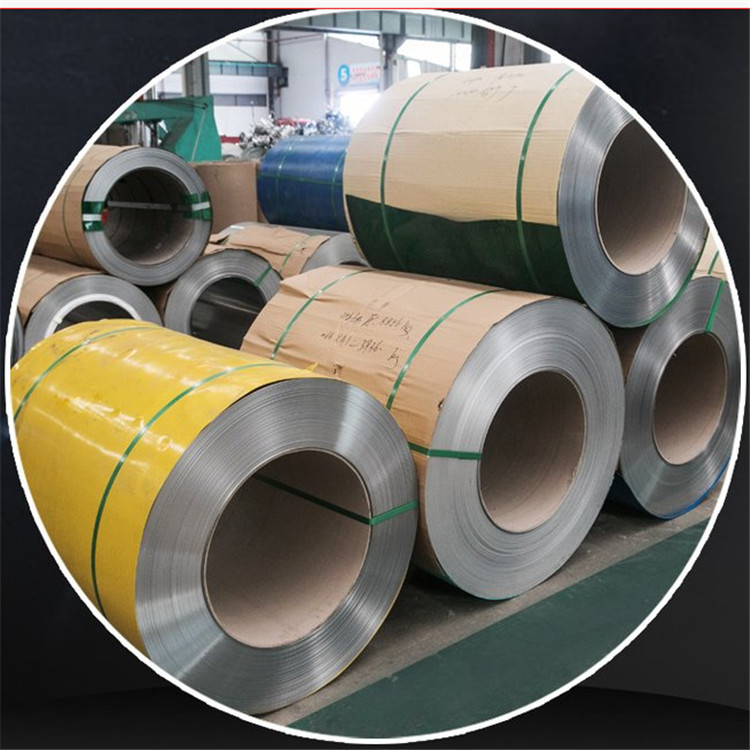

Stainless steel coils can be divided into two categories: cold-rolled stainless steel coils and hot-rolled stainless steel coils according to different production processes, and can be divided into austenite, ferrite, martensite and duplex according to different materials. Stainless steel coils in several materials. Like other types of stainless steel sheets, stainless steel coils have strong corrosion resistance and rust resistance, and their excellent quality makes them important industrial raw materials and building materials. Stainless steel coils are widely used in chemical, food, medicine, paper, petroleum, atomic energy and other industries, as well as various parts and components of construction, kitchen utensils, tableware, vehicles, and household appliances

Stainless steel coil coloring method a. High temperature coloring method. One is to use the tempering method to oxidize the stainless steel surface to golden yellow at a certain high temperature in the air. The second is to obtain a black film by oxidation in a molten bath of bicarbonate. b. Low temperature coloring method can be divided into chemical coloring method and electrochemical coloring method. The chemical coloring method has alkaline chemical coloring method and acid chemical coloring method.

Stainless steel coil surface description

After N0.1 hot rolling, it is heat treated and pickled.

2B is cold rolled and then heat treated, pickled or the like, and finally flattened to obtain the proper gloss.

2D cold rolling followed by heat treatment, pickling or similar treatment or a matte surface.

3# 100~200# Grinding belt grinded products.

4# 150~180# grinding belt grinding products.

HL Abrasives of appropriate particle size are polished to a continuous grained surface.

Cold rolled stainless steel coil

Cold-rolled stainless steel coil refers to: cold-rolled steel plate is a steel coil produced by cold rolling. Cold rolling is a steel sheet obtained by further thinning the No. 1 steel sheet to a target thickness under room temperature conditions. It is used to make corrosion-resistant parts, petroleum and chemical pipelines, containers, medical equipment, marine equipment, etc.

Characteristics of cold rolled stainless steel coil

Compared with hot-rolled steel sheet, cold-rolled steel sheet has more accurate thickness, smooth and beautiful surface, and also has various superior mechanical properties, especially in terms of processability. Because cold-rolled raw coils are relatively brittle and hard, and are not suitable for processing, cold-rolled steel sheets are usually required to be annealed, pickled and surface smoothed before being delivered to customers. High strength (high hardness), high surface finish, generally thin plate, can be used as stamping plate

The classification and grades of cold rolled stainless steel coils are as follows:

1. Austenitic steel: In addition to the same as the hot rolled part (29 types), there are: (1) 2Cr13Mn9Ni4 (2) 1Cr17Ni7 (3) 1Cr17Ni8

2. Austenitic-ferritic steel: In addition to the same as the hot-rolled part (2 types), there are: (1) 1Cr18Ni11Si4AlTi (2) 1Cr21Ni5Ti

3. Ferritic steel: In addition to the same as the hot-rolled part (9 kinds), there are also: 00Cr17

4. Martensitic steel: In addition to the same as the hot rolled part (8 kinds), there are 1Cr17Ni2

5. Precipitation hardening steel: the same as the hot rolled part

Stainless steel hot rolled coil

Hot-rolled stainless steel coils are made from hot-rolled stainless steel strips after further hot rolling. Compared with cold rolling, it has higher dimensional accuracy, lower surface roughness, better surface quality, smoothness and higher strength. Therefore, a thinner hot-rolled strip can be used instead of a thicker cold-rolled strip for the same purpose to save the amount of steel, which is of great economic significance. This product has the tendency to partially replace the cold-rolled sheet, the price is moderate, and it is deeply loved by the majority of users. The hot-rolled stainless steel coil has a smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion by acid, alkaline gas, solution and other media. It is an alloy steel that does not rust easily, but not absolutely rust-free.

Advantages of hot rolled stainless steel coil

Hot-rolled stainless steel has low hardness, easy processing and good ductility. The mechanical properties are far inferior to cold working, and inferior to forging, but have better toughness and ductility. The strength is relatively low, the surface quality is poor (there is oxidationlow finish), but the plasticity is good, generally medium and thick plates.

Several uses of hot rolled stainless steel coil

1. Structural steel coils: production of general structural steel and welded structural steel, mainly used for the production of steel structural parts, bridges, ships and vehicles.

2. Weather-resistant steel coil: adding special elements (P, Cu, C, etc.), with good corrosion resistance and atmospheric corrosion resistance, used in the production of containers, special vehicles, and also used in building structures.

3. Steel coil for automobile structure: high-strength steel plate with good DRAWING performance and welding performance, used in the production of automobile FRAME, WHEEL, etc.

4. Hot-rolled special steel coils: carbon steel, alloy steel and tool steel for general mechanical structures, which are used in the production of various mechanical parts after heat treatment.

5. Cold-rolled raw coils: used to produce various cold-rolled products, including CR, GI, color-coated sheets, etc.

6. Steel plate coils for high pressure vessels and steel plate coils for steel pipes: with good processing performance and compressive strength, they are used to produce high-pressure gas pressure vessels filled with LPG, acetylene gas and various gases with an inner volume of less than 500!

7. Stainless steel coil: Stainless steel coil has good corrosion resistance and is mainly used in the food industry, surgical equipment, aerospace, petroleum, chemical and other industries.

How to choose hot rolled and cold rolled painted stainless steel coil

Cold rolled stainless steel coil

1. Due to a certain degree of work hardening, the toughness is low and the price is more expensive;

2. The processed surface has no oxide scale, and the quality is good;

3. The product made by cold deformation has high dimensional accuracy and good surface quality;

4. Cold rolling is widely used in all walks of life due to its production process, such as all kinds of cold stamping parts, cold rolled cold extrusion profiles, cold coil springs, cold drawn wires, cold heading bolts, etc.

Hot-rolled stainless steel coil

1. Poor toughness and surface flatness, low price;

2. The temperature of hot rolling is similar to that of forging;

3. There is oxide skin on the surface of hot rolling, and the thickness of the plate is different;

4. Due to its production process, it is used in many civilian applications, such as kitchen utensils, general household appliances, etc.;

5. The mechanical properties are far inferior to cold working and inferior to forging, but have better toughness and ductility.