What is the difference between pre galvanized sheet and galvanized sheet?

Pre galvanized steel sheet: steel sheet whose surface is prepared to be galvanized. Galvanized sheet: steel sheet with a layer of zinc on the surface. Galvanized steel sheet is coated with a layer of metal zinc on the surface of the steel sheet to prevent corrosion on the surface of the steel sheet and prolong its service life. This kind of galvanized steel sheet is called galvanized steel sheet.

The pre galvanized sheet corresponds to the post galvanized sheet

For the production of galvanized steel sheet, the steel sheet that has not been galvanized can be purchased from the factory, which is called pre galvanized steel sheet.

Purchase black iron sheet, punch it into the desired steel sheet shape, and then galvanized, that is, post galvanized.

In practice, the fabrication method of galvanized cable tray after long use is more beneficial to anti-corrosion. Then the purchase of pre galvanized steel sheet is not limited by the inherent familiarity of galvanized steel sheet. According to the specific functional needs, we can customize galvanized steel sheet, color coated galvanized steel sheet and so on.

How to process pre galvanized steel sheet?

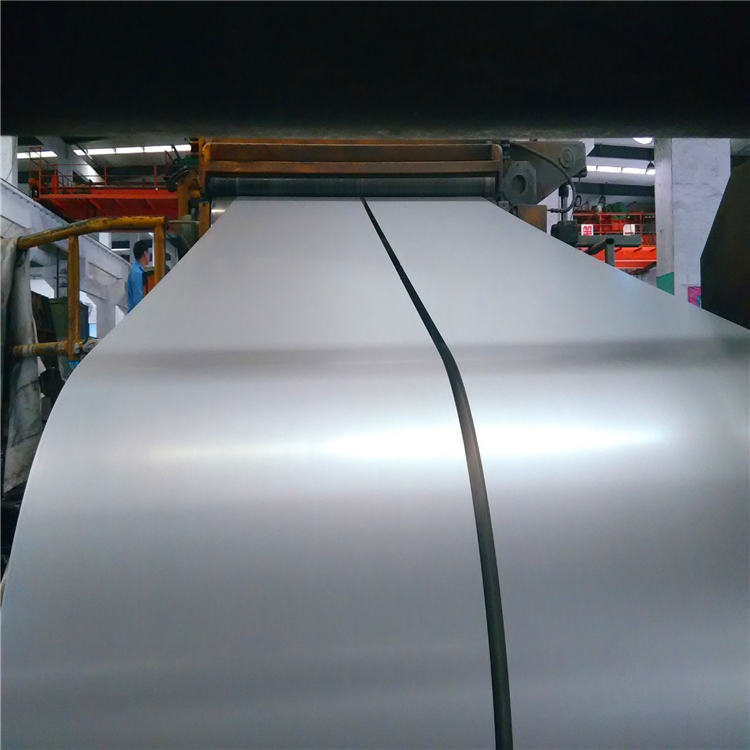

Galvanized steel sheet refers to the steel sheet with a layer of zinc on the surface. Galvanizing is an economical and effective rust prevention method often used. About half of the world's zinc production is used in this process.

What is the classification and function of galvanized sheet?

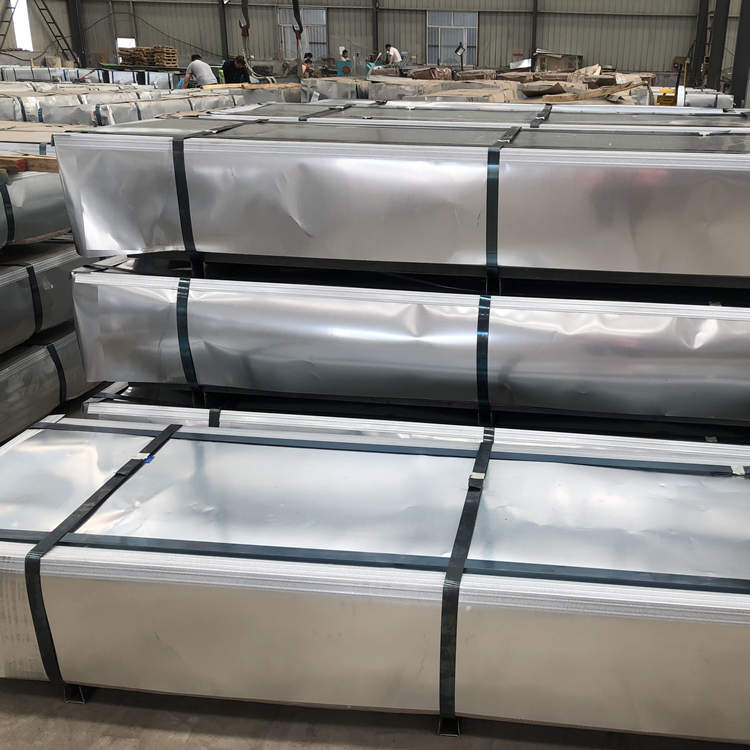

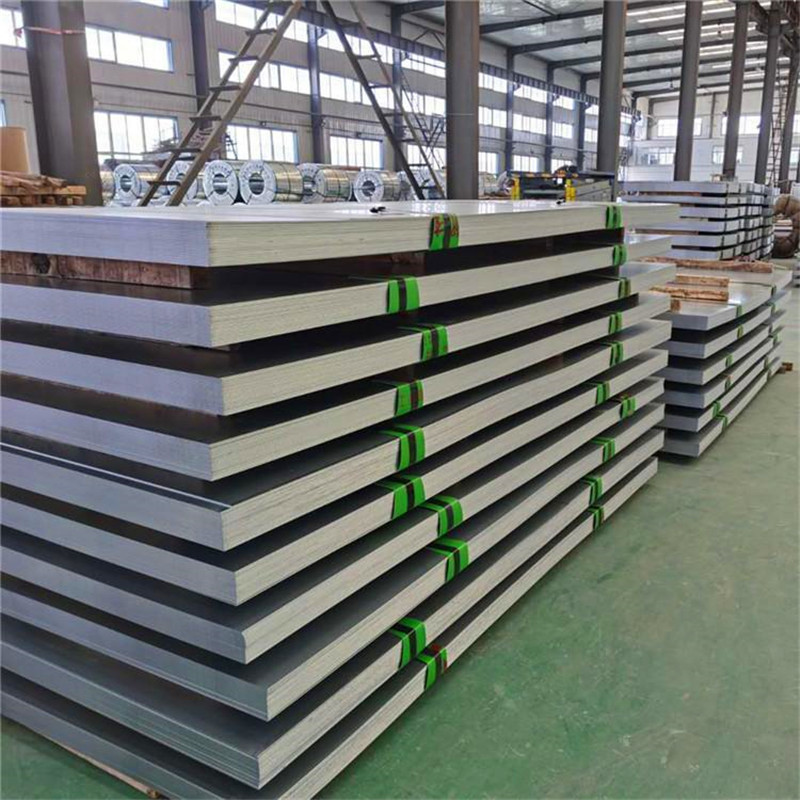

Galvanized steel sheet is coated with a layer of metal zinc on the surface of the steel sheet to prevent corrosion on the surface of the steel sheet and prolong its service life. This kind of galvanized steel sheet is called galvanized steel sheet. According to the production and processing methods, it can be divided into the following categories:

① Hot dip galvanized steel sheet. A sheet of steel immersed in a molten zinc bath to adhere a layer of zinc to its surface. At present, it is mainly produced by continuous galvanizing process, that is, the rolled steel sheet is continuously immersed in the zinc melting bath to make galvanized steel sheet;

② Alloyed galvanized steel sheet. This kind of steel sheet is also made by hot dip method, but after it is out of the groove, it is immediately heated to about 500 ℃ to form an alloy film of zinc and iron.

The galvanized sheet has good coating adhesion and weldability

Thermal reflectance: the thermal reflectance of aluminum zinc sheetd steel sheet is very high, which is twice that of galvanized steel sheet. People often use it as heat insulation material.

Heat resistance: aluminum zinc alloy steel sheet has good heat resistance and can withstand a high temperature of more than 300 degrees Celsius. It is very similar to the high-temperature oxidation resistance of aluminum sheetd steel sheet. It is often used in chimney tubes, ovens, illuminators and fluorescent lampshades.

Good corrosion resistance: the corrosion resistance of aluminized zinc steel coil is mainly due to the protection function of aluminum and aluminum. When zinc is worn, aluminum forms a dense layer of alumina, preventing corrosion-resistant substances from further corroding the interior.

Economy: because the density of 55% Al Zn is smaller than that of Zn, the area of aluminum zinc sheetd steel sheet is more than 3% larger than that of gold sheetd steel sheet under the condition of the same weight and the same thickness of gold plating layer.

Excellent adhesion between paint and zinc plating sheet.

The electro galvanizing layer is thin, the production capacity is low, there is no hot galvanizing, and the anti-corrosion effect is good! One is adsorbed through the action of electric field, and the other is stuck like dipping paint. Electroplating takes the galvanized sheet as a polar sheet, and zinc is sheetd through electronic adsorption, and the coating is uniform. Hot plating is to melt zinc at a temperature higher than the melting point of metal zinc and adsorb it on the sheetd sheet. Poor uniformity.

In this way, after understanding the pre galvanized steel sheet and galvanized steel sheet, you can know that the pre galvanized steel sheet has better flexibility and can be processed into the desired galvanized steel sheet through different processes according to the needs of the purpose. This can meet the different needs of different customers and enhance their competitive advantage.

Pre galvanized steel sheet disadvantages

The preservation shall strictly comply with the standard, because without the protection of zinc coating, it is easier to receive corrosion, resulting in the reduction of the quality of galvanized sheet in the future.

Generally, it cannot be used directly. Pre galvanized sheet is usually used as a substitute for processed steel sheet, and it is rarely used directly in the market.

A certain processing capacity of pre galvanized steel sheet is required. To convert the use of pre galvanized steel sheet, you need to have a certain steel sheet processing ability.