Cold rolled plate

Cold rolled plate

Cold rolled plate is made of hot rolled coil and rolled below the recrystallization temperature at room temperature, including plate and coil. The delivered in pieces is called steel plate, also known as box plate or flat plate; the delivered in coils with long length is called steel strip, also known as coil plate; Plates with a thickness of more than 0.15mm are called plates, 0.15mm Below 15mm is called foil.

Common specification: the minimum thickness is 0.2-4mm, the width is 600-2000mm, and the length of steel plate is 1200-6000 mm.

Common brand: q195a-q235a, q195af-q235af, q295a (b) - Q345 a (b); SPCC、SPCD、SPCE、ST12-15; DC01-06

Common performance: low carbon steel is mainly used. It is required to have good cold bending and welding performance and certain stamping performance.

Cold rolled plate has good performance, that is, through cold rolling, cold rolled strip and steel plate with thinner thickness and higher precision can be obtained. It has high flatness, high surface finish, clean and bright surface of cold rolled plate, easy coating processing, many varieties and wide applications. Because it has not been annealed, its hardness is very high (HRB greater than 90) and its machining performance is very poor. It can only carry out simple directional bending less than 90 degrees (perpendicular to the coiling direction). At the same time, it has the characteristics of high stamping performance, non aging and low yield point, so cold rolled sheet has a wide range of applications, mainly used in automobile and electrical products Locomotive and rolling stock, aviation, precision instruments, food cans, printing drums, construction, building materials, bicycles and other industries. At the same time, it is also the best material for the production of organic coated steel plates.

For general use or stamping

Specifications | yield strength | tensile strength | elongation% |

<0.60m | 275-440 28 | Sound, no crack <0.40mm ≤210 | 275-380 ≥33 |

0.60-1.00mm | 275-440 30 | Sound, no crack 0.40-0.60mm ≤210 275 | 380 ≥34 |

1.00-1.60mm - | 275-440 32 | Sound, no crack 0.60-1.00mm ≤210 275 | 380 ≥36 |

1.60-2.00mm | 275-440 34 | Sound, no crack 1.00-1.60mm ≤210 275 | 380 ≥37 |

1.60-2.00mm | ≤210 | 275 | 38 |

Folding performance and specifications

Variety | Standard Number | Kinds of brands | Uses and features |

cold rolling thin steel | GB700-88 | Hard roll SPCC-1B | Low yield point, wide stamping plasticity area, good shape stability |

Bright annealed soft plate | SPCC-SD | Bright annealed soft plate, SPCC-SD | Low yield point, wide stamping plasticity area, good shape stability |

Cold rolled deep drawing steel strip | SPCD | SPCD | Better stamping performance, and not produce slip line |

Cold rolled super deep drawing steel strip | SPCE | SPCE | Excellent stamping forming performance, can reduce the stamping pass |

1450mm cold rolled sheet

Trade name | standard | Standard Number | Marks | Size |

Cold rolled coilGB | GB11253-89 | SPCC*ST12*SPCC-SB*SPCC-B* | ST12-SD*ST12-SB*ST12-B*Q195 | 0.20-1.2*800-1250 |

Cold rolled sheet GB | GB11253-89 | SPCC*ST12*SPCC-SB*SPCC-B* | ST12-SD*ST12-SB*ST12-B*Q195 | 0.20-1.2*800-1250*(1600-2500) |

Cold rolled sheet different terms

Cold rolled ordinary steel sheet: it is made of ordinary carbon structural steel or low alloy structural steel by cold rolling. The surface quality of cold rolled sheet is good. Good stamping performance. It is required to ensure that the cold bending and cup test are qualified. It is commonly used in automobile and other industries and raw materials of coated plates.

Cold rolled high-quality steel sheet: it mainly includes all kinds of high-quality steel cold-rolled sheets. The most commonly used is carbon structural steel sheet, especially cold-rolled steel sheet for deep stamping. It is a thin sheet cold-rolled by low-carbon high-quality steel 08Al. The steel sheet is divided into three groups according to surface quality; I, II and III respectively represent particularly high-grade, high-grade and high-grade finished surfaces. According to the drawing level, they are divided into ZF, HF and f (representing the most complex, very complex and complex parts used for stamping and drawing). According to the allowable deviation of steel plate thickness, they are divided into a and B accuracy, which are widely used in automobile and tractor industry.

Cold rolled steel plate, with smooth surface and excellent processing, is used for automobiles, refrigerators, washing machines and other household appliances, industrial equipment and various building materials. With the development of economy, cold rolled steel sheet has been called the necessary material in modern society. Classification of cold rolling products: hot rolling pickling, hard rolling coil, ordinary cold rolling, galvanizing (electro galvanizing, fingerprint resistance, hot galvanizing), aluminum zinc plating, electro tin plating, color coating, electrical steel (silicon steel sheet), etc.

Production process

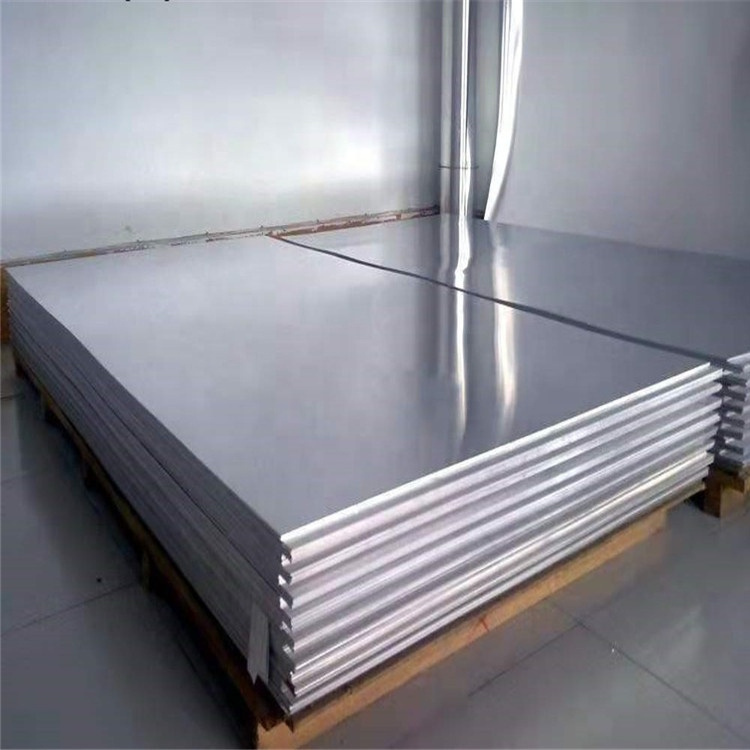

Due to no heating in the production process, there are no defects such as pitting and iron oxide scale often occurred in hot rolling, with good surface quality and high finish. Moreover, the dimensional accuracy of cold rolled products is high, and the performance and structure of products can meet some special application requirements, such as electromagnetic performance, deep drawing performance and so on.

General requirements for acceptance

Each batch of steel plates delivered in the warranty must have quality assurance documents. The type of inspection documents shall comply with the provisions of ASTM A6M, etc., and the handwriting shall be clear without any alteration trace.

The size, thickness and length deviation of steel plate are within the allowable deviation

Attention shall also be paid to the surface flatness, waviness, appearance and corrosion grade of the steel plate

Why us

Timely delivery, abundant stock, 100 distribution personnel to serve you.

Honest operation, with annual sales of 5 million tons and annual sales of 600 million US dollars.

Free technical training, operation guidance and installation services let you have no worries.

Welcome small orders, large quantity and excellent price. Accept customization and quick quotation.