1.Product specification

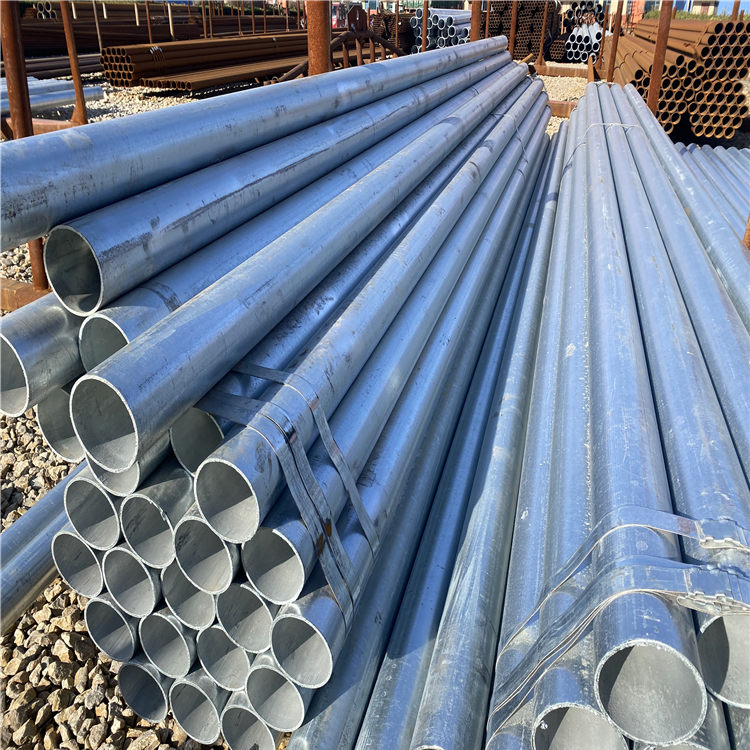

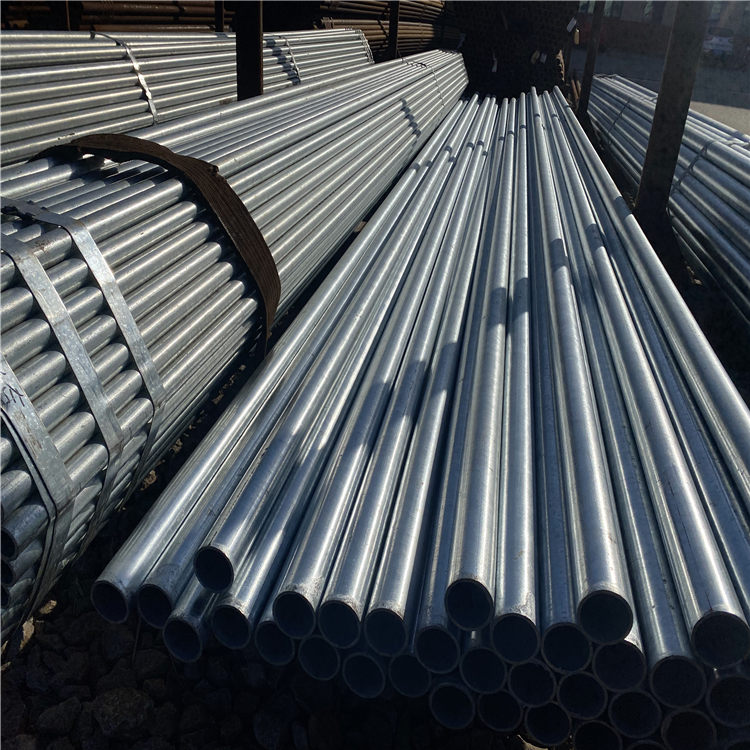

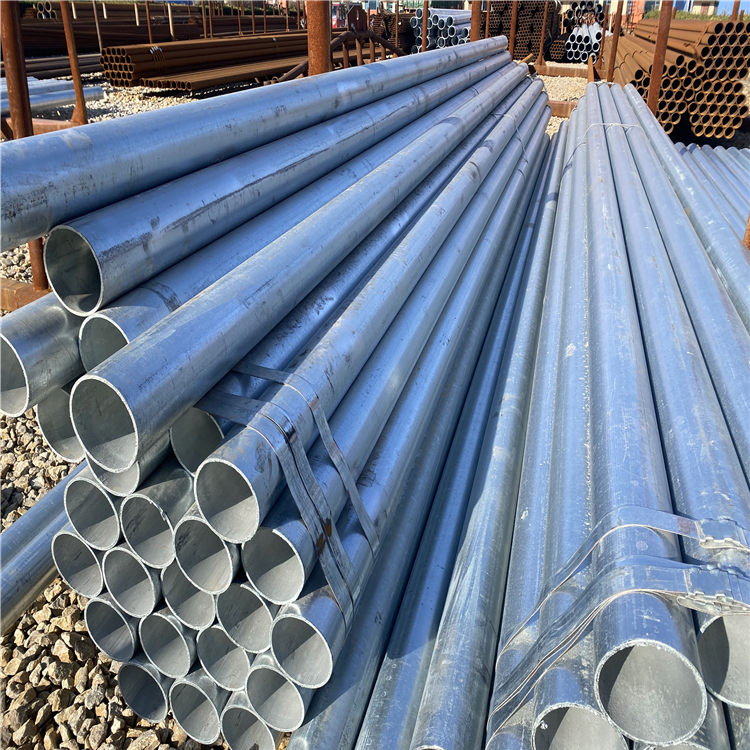

| Product specification | |||

| specifications | Outer diameter(unit:mm) | wall thickness (ordinary)(unit:mm) | wall thickness (upset) |

| 1/2 | 21.3 | 2.75 | 3.25 |

| 3/4 | 26.8 | 2.75 | 3.5 |

| 1 | 33.5 | 3.25 | 4 |

| 1.25 | 42.3 | 3.25 | 4 |

| 1.5 | 48 | 3.5 | 4.25 |

| 2 | 60 | 3.5 | 4.5 |

| 2.5 | 75.5 | 3.75 | 4.5 |

| 3 | 88.5 | 4 | 4.75 |

| 4 | 114 | 4 | 5 |

| 5 | 140 | 4.5 | 5.5 |

| 6 | 165 | 4.5 | 5.5 |

| 8 | 219.1 | 5.5 | 6.5 |

2.product quality performance

| Chemical composition and performance advantages | |

| chemical composition | performance advantages |

| carbon and silicon | Improve the hardness of steel |

| phosphorus | make the cutting of low carbon steel easy to break,improve the machinability of steel |

| manganese | Improve the strength,wear resistance of steel |

| thungsten | Improve the red hardness, thermal strength,wear resistance of steel |

| chromium | Improve the hardenability and wear resistance of steel, improve the corrosion resistance,oxidation resistance of steel |

| zinc | Improved corrosion resistance |

3.Multiple cutting methods

The hot dip galvanized steel pipe is usually 6 meters, but sometimes 3 meters may be needed in some parts of the project, at this time it is necessary to cut the hot-dip galvanized steel pipe. There are many ways and tools to cut, depending on personal choice. Personal skills are part of the story. In the cutting of hot dip galvanized steel pipe, we can use a general cutting machine.In order to ensure that the pipeline processing is not deformed, it is important to choose the cutting machine that meets your welding requirements. The cutting machine is not the same, the way of cutting will be different, and there are some other ways. Japan is now commonly used in agricultural production system mechanical cutting, flame cutting and water cutting these several ways, these three ways can ensure that the pipeline is not deformed.

Firstly:Mechanical cutting using external installation and internal installation of two, the use of turning tool processing principle of the pipe mouth cut off and beveling processing, single span, processing thickness, less waste, pure, processing process does not produce high temperature, does not affect the pipeline material, conducive to welding. Water cutting through high pressure pump and emery joint action processing pipeline, the incision is clean, processing span is large, but its low efficiency, processing thickness limited factors are serious.

Secondly:Oxygen acetylene flame cutting, by adjusting the oxygen valve and acetylene valve, can change the mixing ratio of oxygen and acetylene to get three different flames: neutral flame, oxide flame and carbonization flame.

Thirdly:Plasma cutting, plasma cutting with different working gas can cut all kinds of oxygen cutting difficult to cut metal, especially for non-ferrous metals (stainless steel, aluminum, copper, titanium, nickel) cutting effect is better; Its main advantages lie in the cutting thickness of the metal, plasma cutting speed is fast, especially in the cutting of ordinary carbon steel sheet, the speed can reach the oxygen cutting method 5~6 times, cutting surface smooth, small thermal deformation, less heat affected area.

These methods are also commonly used in pipe cutting.