What is hot dip galvanized pipe

What is hot dip galvanized pipe

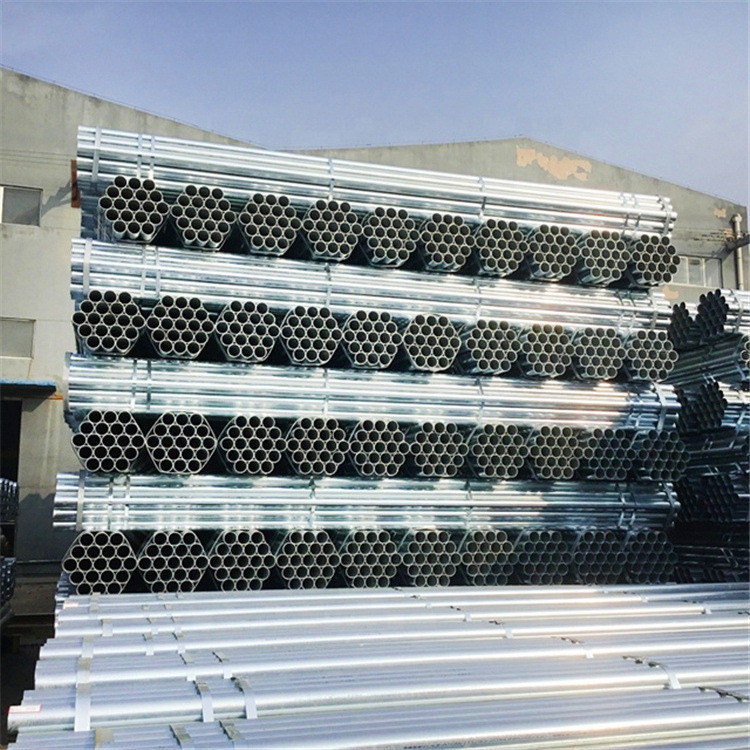

Galvanized steel refers to ordinary carbon construction steel after galvanized processing can effectively prevent corrosion and rust of steel to prolong the service life of steel, which is divided into electric galvanized and hot dip galvanized. Generally used for building exterior walls, such as glass curtain wall, marble curtain wall, aluminum curtain wall as columns and stress materials, or used for outdoor telecommunications towers, highways and other open-air buildings. Pipelines for water, gas, oil and other general low pressure fluids, oil well pipes and pipelines in the petroleum industry in the offshore oil fields, oil heaters, condensing coolers of chemical coking equipment, pipes for coal distillation and washing oil exchangers, pipe piles on trestle Bridges, pipes for supporting frames in mine tunnels, etc.

Hot-dip galvanized steel pipe

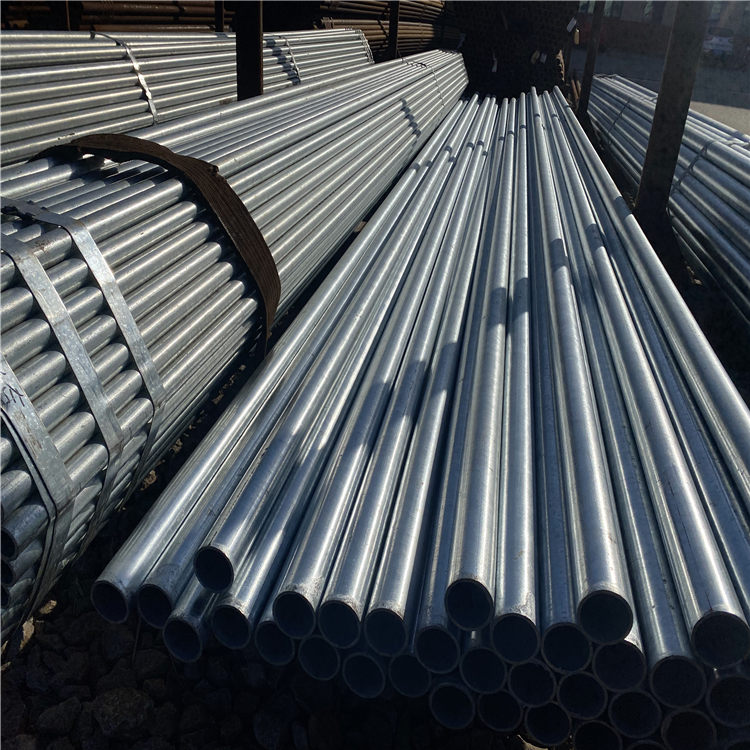

Hot dip galvanized tube is to make molten metal and iron matrix reaction and produce alloy layer, so that the matrix and coating of the combination of the two. Hot dip galvanizing is the first steel pipe pickling, in order to remove iron oxide on the surface of the steel pipe, pickling, through ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank for cleaning, and then into the hot dip plating tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between hot dip galvanized steel tube and molten plating solution to form a tightly structured zinc-ferroalloy layer with corrosion resistance. Alloy layer is integrated with pure zinc layer and steel tube matrix. So its corrosion resistance is strong.

Cold galvanized pipe

Cold galvanized pipe is electric galvanized, galvanized quantity is very small, only 10-50g/m2, its own corrosion resistance is much different than hot galvanized pipe. Regular galvanized pipe manufacturers, in order to ensure quality, most do not use electric galvanized (cold plating). Only those small, outmoded small businesses use galvanizing, and of course their prices are relatively cheap. At present, the Ministry of Construction has officially below, the elimination of backward technology of cold galvanized pipe, the future is not allowed to use cold galvanized pipe for water, gas pipe. The zinc layer of cold galvanized steel tube is electrodeposited, and the zinc layer is separated from the steel tube substrate. Zinc layer is thin, zinc layer simply attached to the steel tube substrate, easy to fall off. So its corrosion resistance is poor. It is forbidden to use cold galvanized steel pipes as water supply pipes in new residential buildings.

Hot dip galvanized steel pipe is galvanized to the surface under the condition of hot dip, its adhesion is very strong, not easy to fall off, although hot dip galvanized pipe rust phenomenon, but in a very long period can meet the technical and health requirements. The corrosion resistance of hot-dip galvanizing is much higher than that of cold galvanizing (also known as electric galvanizing). Hot galvanizing will not rust for years, cold galvanizing will rust in three months. Hot dip galvanizing has thick galvanized layer and low cost of electric galvanizing

Method for removing rust of hot-dip galvanized pipe

1, the first use of solvent cleaning steel surface, the surface of the organic matter removal,

2, then use tools to remove rust (wire brush), remove loose or tilt scale, rust, welding slag, etc.,

3, the use of pickling.

Galvanized is divided into hot plating and cold plating, hot plating is not easy to rust, cold plating is easy to rust.